Understanding closed-loop and open-loop recycling

Recycling plays a crucial role in reducing waste and conserving resources, but not all recycling processes are the same. Two primary methods — open-loop and closed-loop recycling — determine how materials are reused and their long-term sustainability. Understanding the differences between these systems is key to making informed choices about waste management and environmental impact for your business.

So, let’s go through the basics of both open-loop and closed-loop recycling, explore their similarities and differences as well as benefits, and help you identify which system might work best to boost your business’s sustainability.

What is closed-loop recycling?

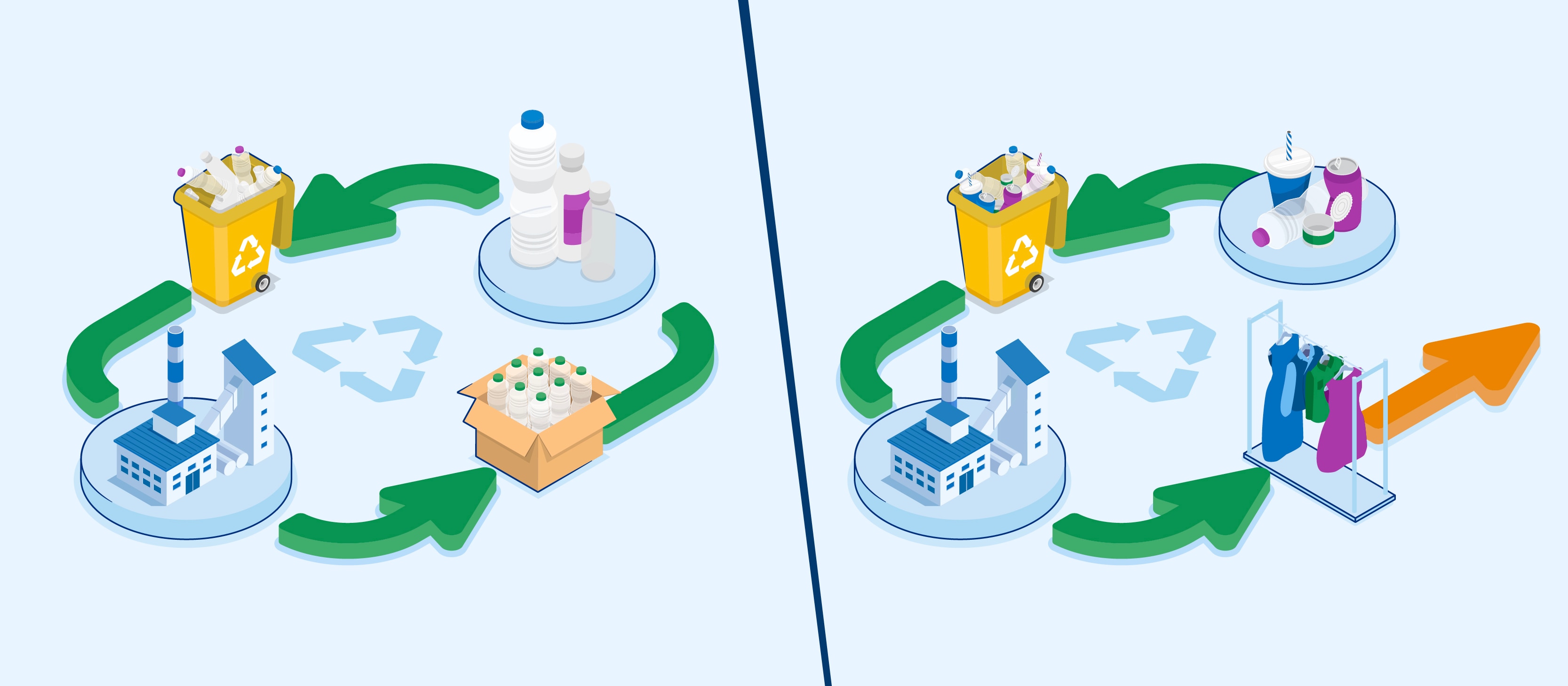

Closed-loop recycling is a methodology where existing manufactured materials are processed repeatedly back into the same or a similar product they were before use. This effectively "closes the loop", preventing used products from ending up in landfill by continuously extending their lifespan. [1]

So, what kind of materials can be recycled in this way? There are three main categories: [2]

- Aluminum cans: can be recycled indefinitely into new cans without any loss in quality.

- Glass bottles: glass can be reprocessed into new bottles without losing purity or durability.

- Cardboard packaging: used cardboard can be recycled into new packaging materials while retaining its strength and structure.

What is open-loop recycling?

Unlike closed-loop recycling, an open-loop system repurposes materials into new products with different uses, rather than continuously recycling them into the same or similar item. This gives new life to the original materials and prevents them from ending up in landfill, reducing CO2 emissions. You may already be familiar with the open-loop system, as this method is the most common for household recycling. Ideal items/materials for open-loop recycling include:

- Some types of plastics: Polyethylene Terephthalate (PET) plastics —commonly used in drinks bottles— can be repurposed into textiles and plastic lumber. While High Density Polyethylene (HDPE) plastics —the type used for detergent bottles, for example— can be used to create plastic pipes or composite wood.

- Textiles: Old clothes, for instance, can be made into secondary products such as insulation, padding, and even cleaning rags for industrial facilities.

- Rubber: Rubber (such as the one from tires) can be used to create mats, playground surfaces, and additives for asphalt.

What are the benefits of closed and open-loop recycling?

While recycling in general is a good way to be mindful of our planet, these two methods help in a few particular ways: [3]

Continuous resource flow

The closed loop recycling system allows materials to be reused in their original form, creating a continuous product life cycle that eliminates the need for additional extraction of virgin materials.

Flexible product creation

The open-loop recycling process provides several options for what goods can be turned into. For example, recycled glass can be turned into construction materials like fiberglass or used as road base.

Waste reduction

Both closed and open-loop recycling help keep used products out of landfills by converting what could have become waste into new products or a new version of the same item. Whichever method you choose reduces the overall volume of waste products that needs to be managed.

Less pollution

These recycling options reduce the need for raw material extraction, which can contribute to environmental damage. According to the United Nations, the extraction and processing of materials, fuels, and food contribute half of total global greenhouse gas emissions and over 90% of biodiversity loss and water stress. [4] This comes to show the big impact that recycling can have.

Lower costs

In general, recycling can help your business’s finances by reducing waste disposal costs. Additionally, depending on your industry, using recycled materials instead of raw ones could potentially optimize your budget. Plus, open-loop recycling can benefit your business by offering cheaper material alternatives for new products, reducing reliance on costly new resources. [5]

Supporting other industries

A unique benefit of open-loop recycling is that because the materials can be used to create entirely new products, if your business does not need them, used resources can support other industries or even your local community.

For example, a textile business could have its fabrics recycled to create fiber insulation for buildings or an automotive business could have old tires transformed into a children’s playground.

Which type of recycling works for which business?

Basically, there’s not necessarily a better option than the other. Whether your businesses can benefit from adopting closed-loop or open-loop recycling depends on the materials you produce.

Closed-loop recycling is particularly beneficial for industries dealing with materials that can be reused indefinitely in their original form. For instance, electronics manufacturers can recycle components like circuit boards and metals into new electronics, reducing the need for virgin resources and minimizing e-waste. Automotive companies can recycle aluminum parts to produce new car components without compromising quality. Paper mills can also use closed-loop recycling to transform old paper into new paper products, ensuring a continuous cycle of material reuse while cutting down on deforestation.

Open-loop recycling, on the other hand, is better suited for industries handling materials that cannot be reused in the same format. Construction companies can repurpose waste materials like concrete, wood, and metals into products such as road construction goods or landscaping products. Furniture manufacturers can recycle textiles and foam from old products, turning them into insulation or other secondary materials. Another example could be shoemakers converting rubber and fabric into new items like playground equipment or mats.

In short, businesses that work with materials suitable for continuous reuse, such as metals and paper, will benefit from closed-loop recycling. Meanwhile, those dealing with goods that degrade or change form, like textiles or construction debris, are better suited for open-loop recycling, helping to divert waste and create new products. Regardless of which one suits your business in particular, both systems can enhance your sustainability efforts and reduce environmental impact.

Understanding the differences between closed-loop and open-loop recycling is key to implementing effective strategies to boost your business’s sustainability. Each method has its advantages, whether it’s the continuous reuse of materials in closed-loop systems or the versatility of open-loop recycling for a broader range of items. At the end of the day, the more you know about your options, the better prepared you can be to make the right choice for your facility.

At Tork, we’re committed to supporting your business’s sustainability goals. We prioritize responsible sourcing and have increased our use of renewable, recycled, and natural content in both our products and packaging. Not only that, but we’ve also designed one-at-a-time dispensing systems to help you reduce waste while upholding high hygiene standards at your facility. Additionally, Tork products can contribute to earning LEED-credits for your business. And these are just a few of our many sustainability initiatives!

To learn more about how your business can also be more mindful of the planet and the people living in it, why not explore our guide on how to improve sustainability in the workplace?

References:

[1] https://lacerta.com/blog/closed-loop-recycling-definition

[2] https://www.roadrunnerwm.com/blog/what-does-it-mean-to-close-the-loop

[3] https://www.commercialzone.com/the-benefits-of-closed-loop-recycling/

[4] https://www.un.org/en/actnow/facts-and-figures

[4] . https://www.e-education.psu.edu/eme807/node/624

[5] https://www.bpf.co.uk/press/closed-and-open-loop-plastic-recycling.aspx