Tork Workflow

Prioritize efficiency & reach your targets

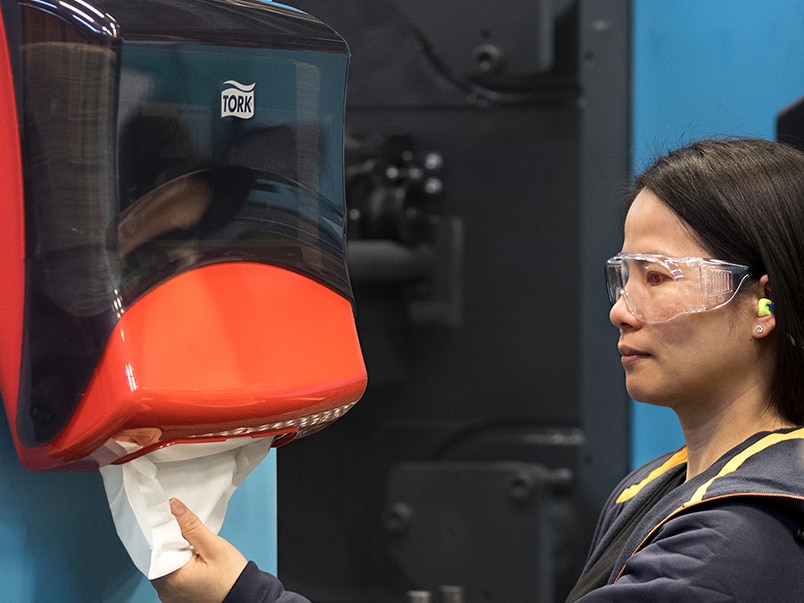

In industrial environments like manufacturing, 9 in 10 employees believe quality tools like wiping and cleaning products boost productivity and even happiness- on the job. Yet, for organizations that use any form of wiper, inconvenient storage and placement somewhere other than point of use can disrupt operational efficiency with wasted motion, inventory and over-consumption.

Let us show you why switching to Tork can help you reach your targets and establish a safer, more efficient facility.

Tork Workflow focuses on four priority areas:

- Productivity

- Waste

- Employee & Customer satisfaction

- Environment, Health & Safety

Securing an efficient workplace - in line with Lean and 5S.

Tork Workflow is a complimentary service allowing you the opportunity to audit your maintenance and

workstation efficiency with one of our field experts. The 60-minute either virtual or in-person session

provides an in-depth look at your facility's operations and offers recommendations based on 5S

principles on how to reach your targets, boost workplace efficiency and cut costs. The Workflow report

also includes a free trial recommendation of Tork products best suited to meet your specific needs.

- Free of charge service

- No purchase necessary

- Free trial available following our assessment